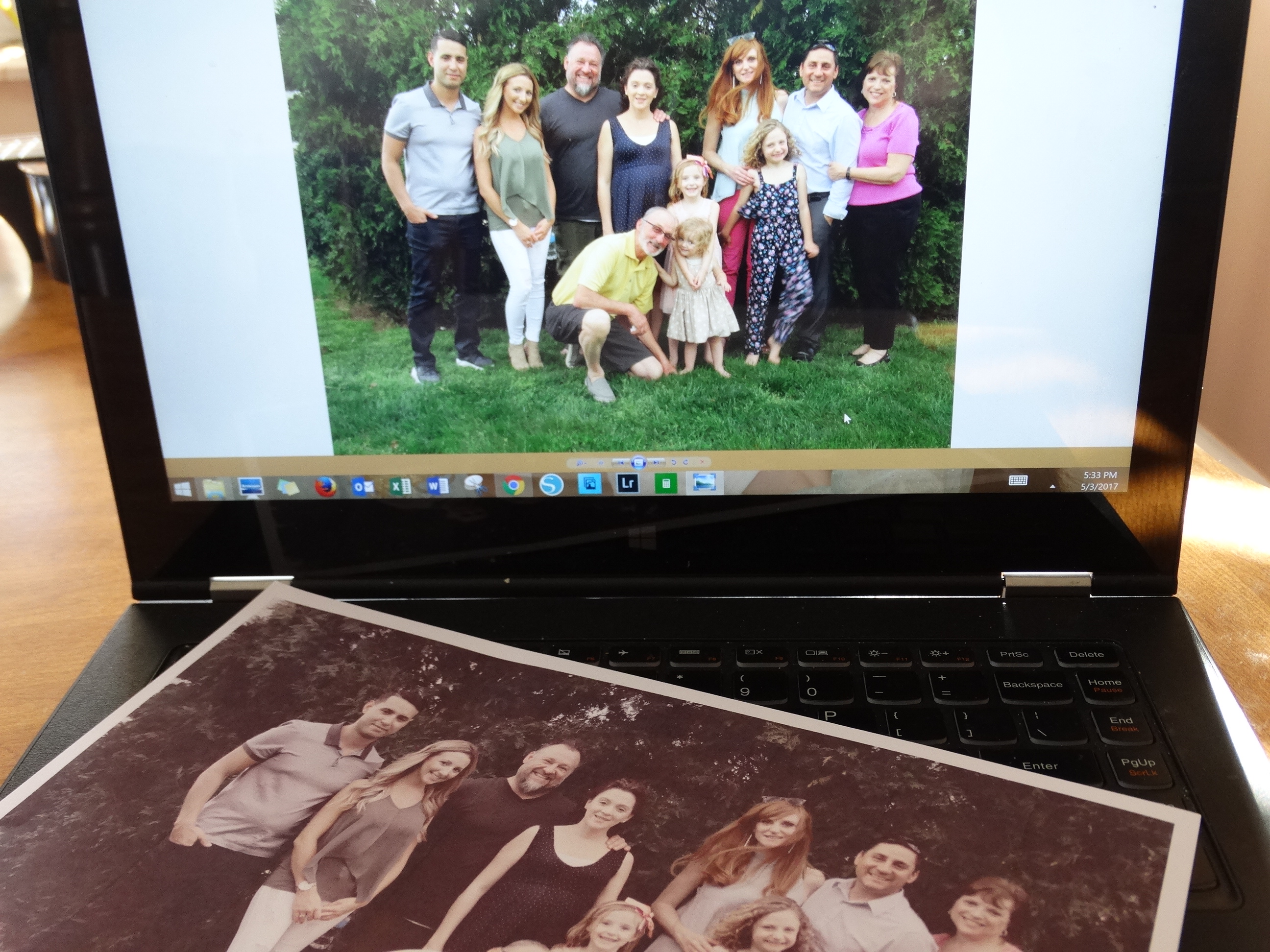

Do you have a sublimation printer? Congratulations! Sublimation printing is a great way to for a businesses to create customized and personalized full-color products on demand. And as you are probably already aware, the production technique is relatively simple. When sublimation inks are heated to 400°F, they turn into a gas and form a permanent bond to 100% white or light color polyester fabric or items that have a polymer coating. The result is a premium full-color, photographic-quality image that will not crack, peel or wash away from the substrate.

As with all good things, there are three common problems that you may encounter at some point. So we’ve compiled a list to help you troubleshoot them quickly.

1. Banding

If you encounter lines of missing ink in your printouts, then you are most likely having banding issues. There are two reasons for banding. The quickest reason to troubleshoot is running out of ink, so be sure to check your ink levels. The second, most common cause is from clogged print head nozzles. Like it or not, ink dries out over time. . . all ink, not just sublimation ink. If this happens inside the print heads, then obviously the flow of ink will be inhibited, which results in streaks of missing ink on the printout.

As long as you are printing on a regular basis – at least several times per week – the ink will not have an opportunity to dry out. However, for long stretches of time with no printer activity, you could have issues.

The simplest way to deal with this is to run a small quantity of ink through the print heads on a routine basis, by using the head cleaning function of your printer. In the case of Virtuoso and Ricoh printers, this is done for you automatically, as long as you leave the printer powered up. However, for Epson printers, you will need to perform a manual head cleaning every few days, which means pushing a button. There are some software programs available that will prompt your printer to perform a head cleaning at specified intervals so that you can set it and forget it as long as you leave everything powered up!

2. Moisture Issues

The introduction of moisture into the sublimation process can cause unwanted results. During production with a heat press operating at 400 degrees, that moisture can flash to steam and blow away the ink from its intended target. Some of the problems that are attributed to moisture include: color shifting (colors lose accuracy), bleeding of the image, and uneven transfer of solid filled areas.

Under normal circumstances, a small amount of moisture can accumulate in your transfer paper, and it’s usually absorbed directly into the substrate during pressing. However, hard substrates like metal and ceramic are unable to absorb excess moisture. Thus, it’s important that you take steps to minimize the introduction of moisture into the process.

The first step is to protect the paper from moisture absorption. As a preventative measure, you should store your paper in dry place. Avoid using Zip-Top plastic bags as they can trap moisture within.

If you suspect moisture, set the paper on your press for a few seconds. Do not press it. Just expose it to the warmth. The heat radiating from the press should help evaporate most of the moisture.

Another trick is to use newsprint or butcher paper instead of a Teflon sheet. The paper will help absorb moisture from the transfer sheet during pressing (Teflon will not). Be sure to use a fresh sheet of paper on each pressing.

If you are working with garments or fabric, it’s also possible that the substrate may contain a bit of moisture. Pre-pressing the garment for about 3 seconds should remove the moisture and any wrinkles as well. Do not overheat the substrate! Applying a sublimated transfer to a hot surface will start the gassing process prematurely, which may lead to ghosting.

Also, you should focus on your work environment. If there is a high level of humidity present, it may be contributing to the moisture issues. A dehumidifier may be necessary to help control moisture issues. However, reducing it too much can have adverse effects on the inks and your equipment. Thus, you should invest in a hygrometer and take some readings. The ideal operating conditions for sublimation are 70o – 80o F with 35% – 65% relative humidity (no condensation).

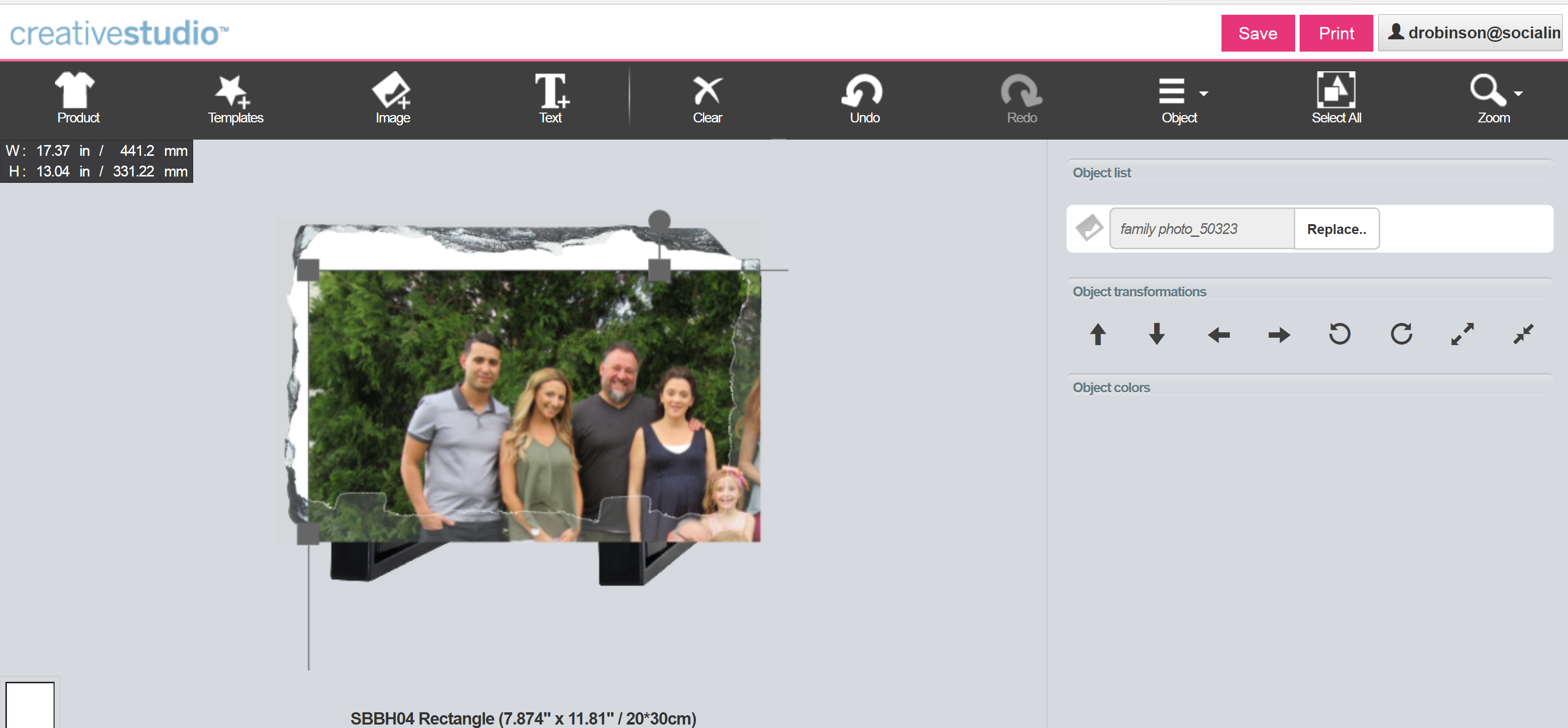

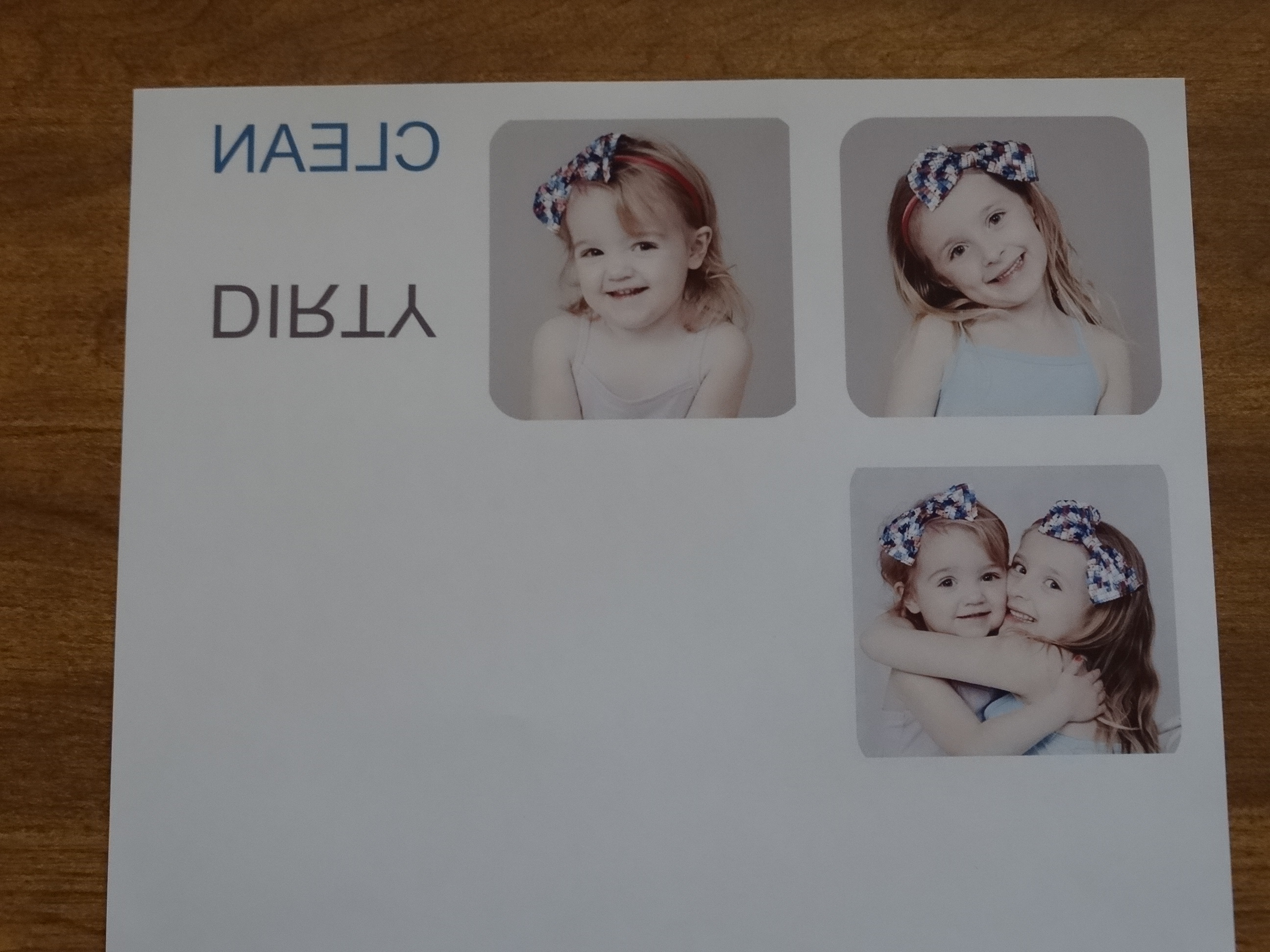

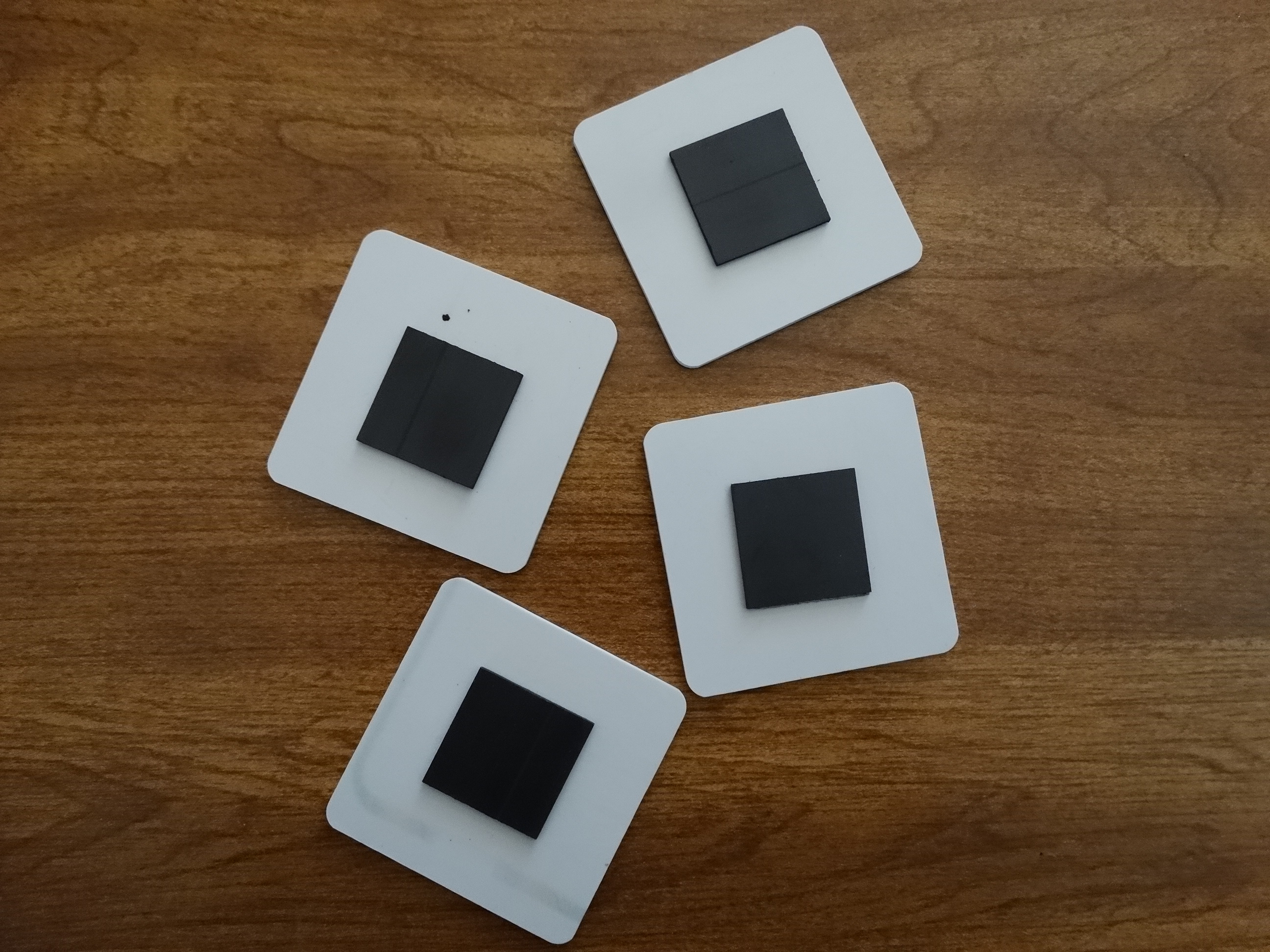

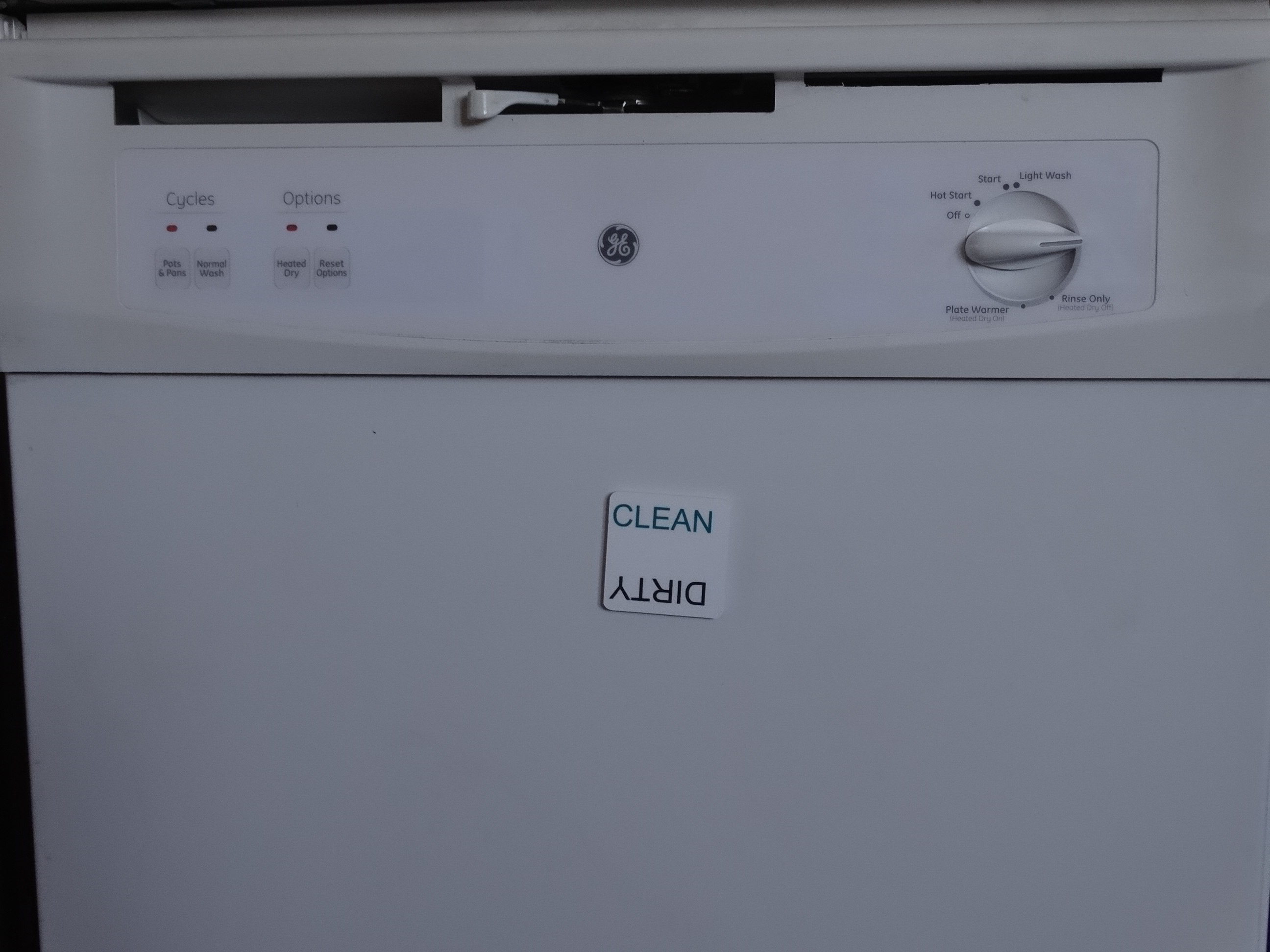

3. Ghosting & Gassing Out

Sublimation requires a tight marriage between the transfer paper and the blank product during pressing. If the paper shifts or is not firmly planted against the substrate, then the result will be ghosting and/or gassing out.

Ghosting is when you end up with a blurry image, typically characterized by a shadow effect along or outside of the edges. Gassing Out is when you end up with a “burst” of ink outside of the image area.

The key to avoiding ghosting is by making sure you have a tight fit between the transfer paper and the substrate. We recommend using a heat resistant tape to secure the transfer to the product. But be careful not to tape across the image area as this can often damage the image quality. Just use a minimal amount of tape along the edges, as you will need to be able to easily and quickly remove the transfer after pressing.

Another option when sublimating apparel is to use “repositionable” adhesive spray instead of tape. Apply a very light mist on the image side of the transfer paper from about 12-18″ away. Do not spray the shirt. If you position it incorrectly, you can lift it off and reposition it. Then press the transfer paper to the product.

Regardless of how you adhere the transfer paper to the product, it’s important that when you remove it, it doesn’t slide along the surface of the substrate, as this may spread sublimation dye into unwanted areas, and cause ghosting. Ideally, with hard substrates, the transfer will be lifted off the surface, quickly and cleanly. With apparel, it may work better to grab one end of the paper and pull it away slowly, while firmly holding the garment down.

These are three of the most common issues encountered when printing with sublimation. Each of them is relatively easy to resolve. If you are still having trouble, make sure you contact your equipment supplier to discuss.

View & Add Comments