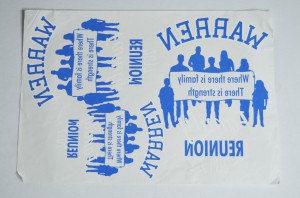

Do you have your own images and graphics you’d like to turn into heat transfers and adhere to garments with your heat press? All you need is Transfer paper. Transfer paper comes in a variety of sizes and is durable and completely washable. Creating your own heat transfers will give you the flexibility to create custom t-shirt designs for a single customer or a whole group.

The first thing when choosing a transfer paper is to consider what type of printer you will be using – inkjet or laser?

Next, check with your printer manufacturer in regards to using transfer paper. We suggest not using transfer papers with brands such as HP, Dell, and Brother. These printers have internal fusers that run too hot and can cause the paper to get stuck in the rollers, ruining the paper and possibly the printer itself.

Laser and inkjet printers both produce a similar quality of the design after pressing. The main difference between inkjet and laser printers is the cost to get started. Inkjet printers are cheaper, but tend to use quite a bit of ink. Laser printers are more expensive, but the toner lasts longer. Laser printers also offer the advantage of trim free paper.

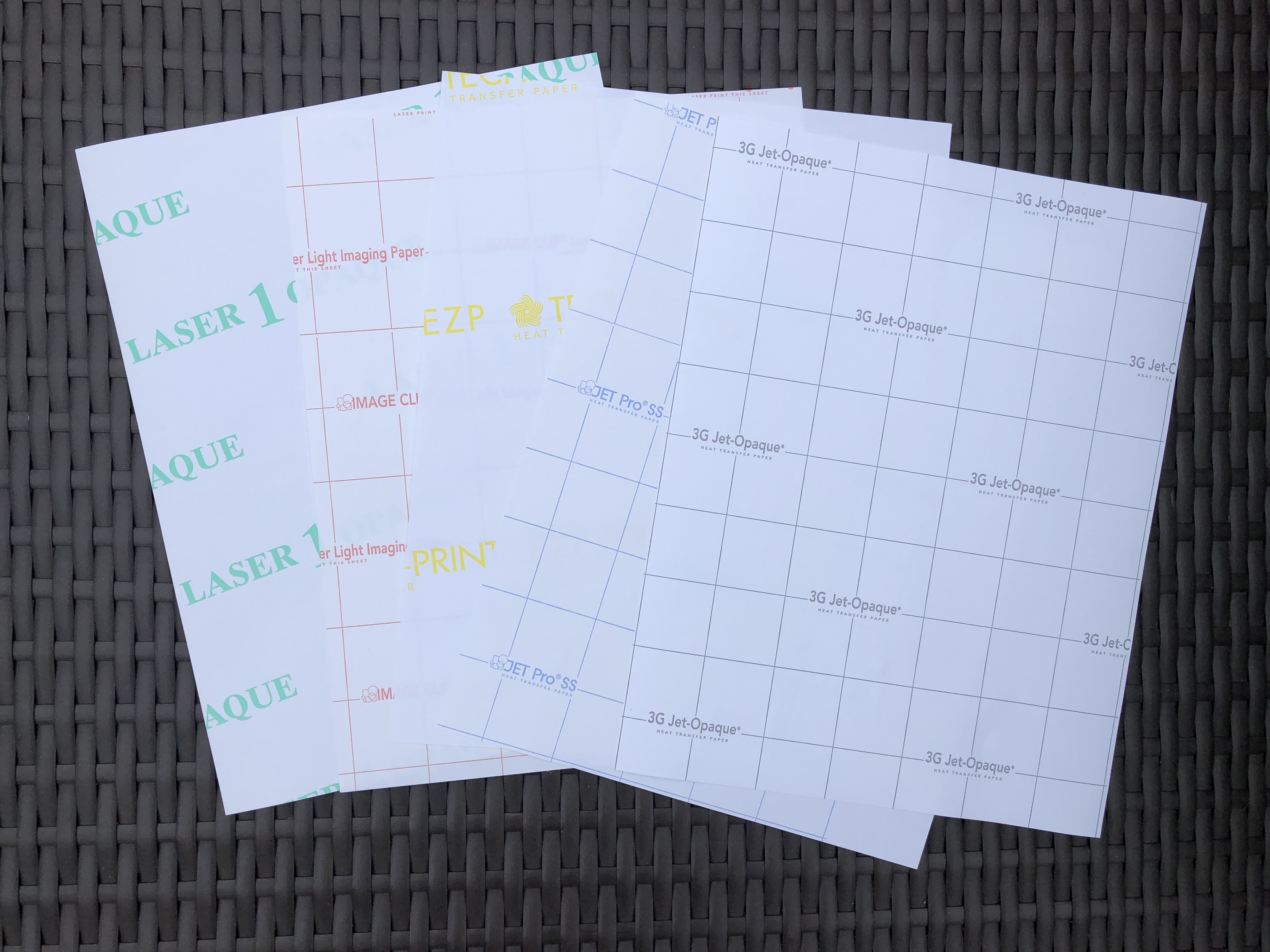

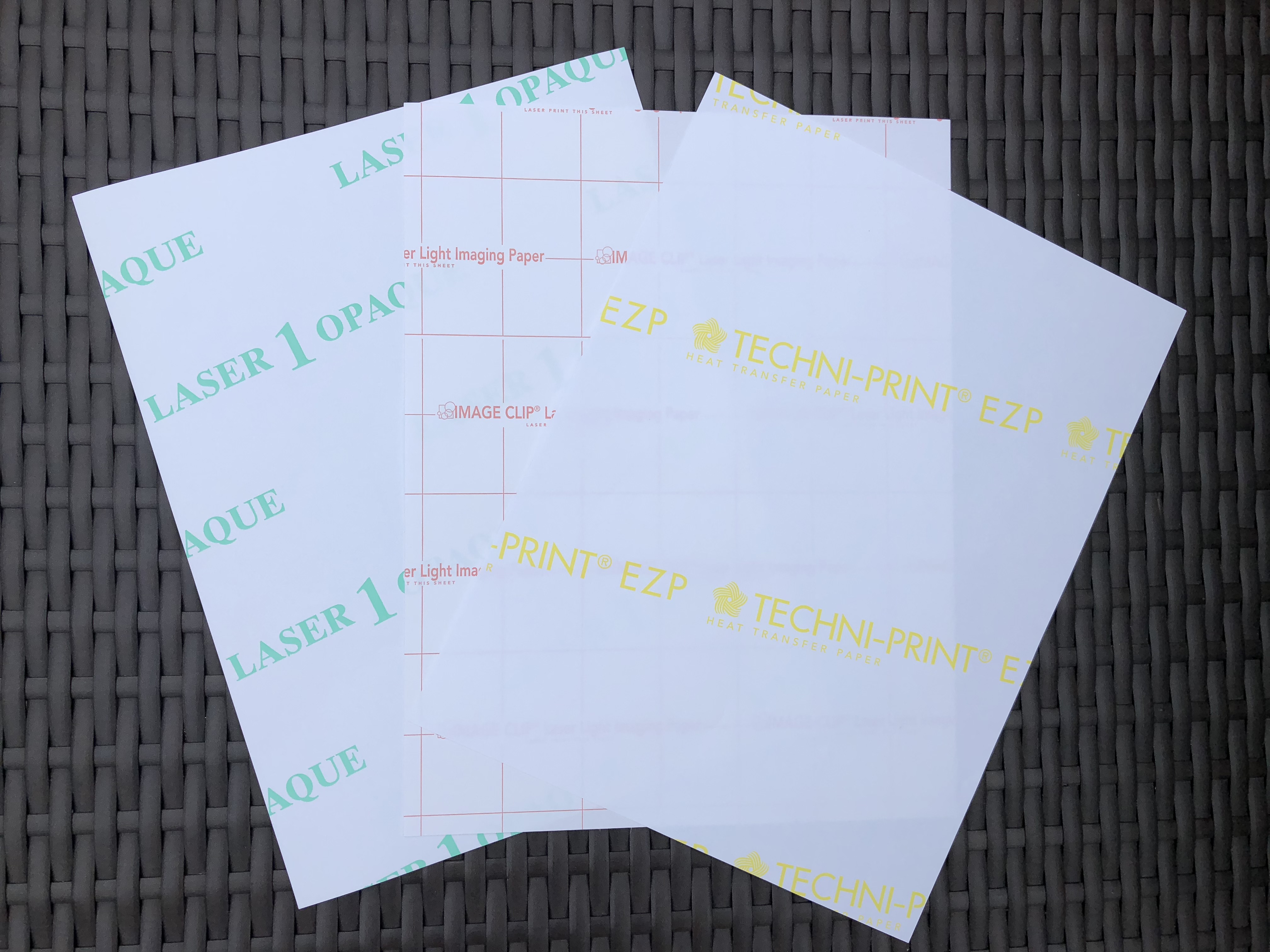

Here are the different types of paper we offer for each printer:

Inkjet Paper:

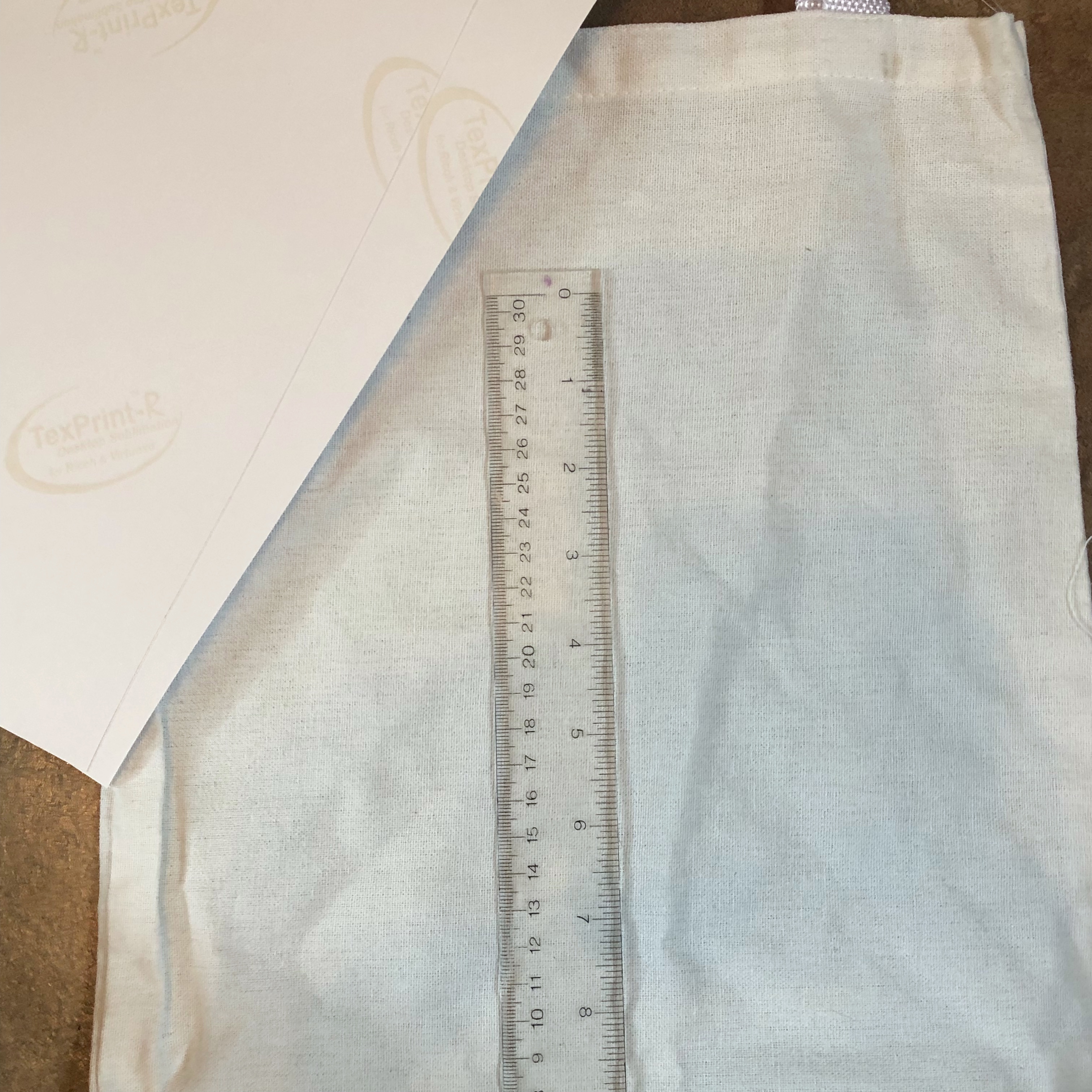

The Jetpro Soft Stretch Inkjet Paper comes in 8.5×11 and 11×17. It produces soft, supple, vibrant, and washable ink jet printed transfers for white and light colored fabrics. It can be used to apply designs and photographs and can be trimmed to reduce the transfer of the background.

3G Opaque Paper comes in 8.5×11 and 11×17. This also produces vibrant and washable transfers but are suitable for dark fabrics. Since you will be printing on a white surface, you’ll want to trim away any area you do not want white before applying. Like the Jetpro, you can use it for basic designs as well as photographs. (This transfer paper is not recommended for Hewlett Packard and Dell Printers).

Laser Printer:

Lasersoft EZ Peel transfer paper comes in 8.5×11 and 11×17. It is the only laser transfer available that allows the inks to absorb into the surface of the coating of the paper. The coating then acts like a shield and later bonds the inks to the fabric fibers without using a plastic film offering a high quality, soft solution for laser transfers.

CLC Paper comes in 8.5×11 and 11×17 and works with both oil and non-oil laser printers. This paper is great for transferring high-resolution photographs and images onto dark materials. Garments with a tight weave work best.

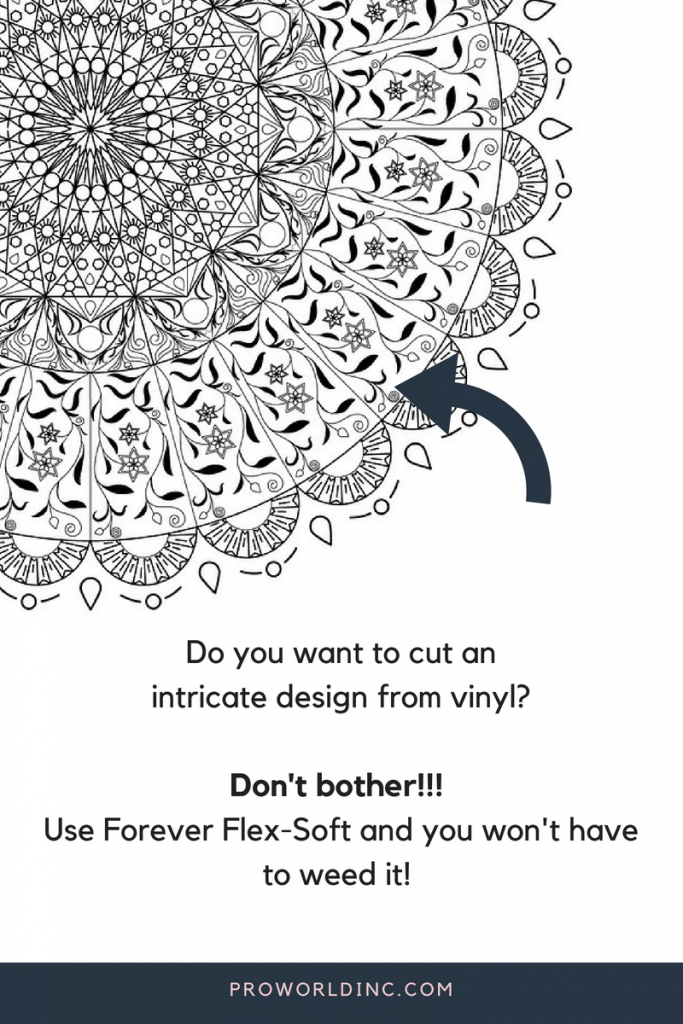

CI Trimfree comes in 8.5×11 and works only on solid, light colors. This is the first single step transfer paper and has been developed to release the polymer coating only in areas that have toner coverage where the image is pressed to the fabric. This makes it so you don’t have to trim your design before pressing it to your garment. Images will stay bright and vibrant, even after continued washing and the paper will print on both oil and non-oil laser printers.

Image Clip Laser Paper comes in 8×10.5 and 10.75×16.75. It works best on light garments and handles full-color designs very well. This paper is self-weeding, so there is no need to trim the excess paper as there will be no background to your printed design, although this paper is a two-step process.

Image Clip Laser Paper for dark, solid garments comes in 8×10.5 and 10.75×16.75. Just like the Image Clip for lights, there is no need to trim the excess paper as this paper is self-weeding. But this paper is not designed for transferring photography.

View & Add Comments